- Duqiao economic development Zone, Jingxian, Hengshui, Hebei China

- (86) 188-3188-7776

- sales@minghose.com

Our news

With over 25 years of experience in all industry branches we've built well known name.

Super User

HPI Pressure Tight Stripwound Metal Hose

HPI Pressure Tight Stripwound Metal Hose

Description

Pressure-tight technical hose made by helically winding a pre-formed metal strip into a fully interlocked hose and inserting into the lock section a high temperature composite packing for fluid tightness.

Principal Applications

Conveyance of corrosive fluids, bitumen, oxygen, steam, abrasive and pulverised products. HPI is a strong robust hose.

Standards:Manufactured to the specifications where applicable of ISO 15465 Type DOP.

Pressure Capability

The nominal working pressure stated has a safety factor to burst pressure of 3:1. The burst pressure is measured with the hose being straight and motionless under internal hydrostatic pressure at ambient temperature.

Materials of Construction and Temperature

Galvanized steel/Stainless Steel AISI 304

Composite packing - up to +200°C - service life of the hose reduces significantly at elevated temperatures above 200°C

Fitting Attachment

We strongly recommend the use only of packed on reattachable fittings if hose is to be used for liquid use. Welding of this hose is not recommended as the welding process could damage the packing in the hose creating a leak path.

Supply Lengths - standard: 19-150mm9, 15 meters/175-200mm9 meters

Longer lengths available on special order.

|

Inside Nominal bore |

Inside Nominal bore |

Outside Nominal bore |

Nominal Pressure |

Nominal Pressure |

Bend Radius |

Bend Radius |

Weight Metre |

|

(mm) |

(inches) |

(mm) |

(Galv)

|

(SS304)

|

(Static)

|

(Dynamic)

|

(kg) |

|

19 |

3/4” |

24 |

31 |

32 |

150 |

180 |

0.87 |

|

25 |

1” |

30 |

27 |

32 |

205 |

215 |

1.07 |

|

32 |

1 1/4” |

37 |

22 |

32 |

230 |

255 |

1.25 |

|

38 |

1 1/2” |

45 |

20 |

31 |

280 |

355 |

2.05 |

|

50 |

2” |

57 |

17 |

26 |

340 |

430 |

2.65 |

|

63 |

2 1/2” |

71 |

16 |

20 |

430 |

485 |

4.24 |

|

75 |

3” |

83 |

14 |

17 |

485 |

565 |

4.86 |

|

100 |

4” |

110 |

11 |

14 |

575 |

750 |

7.75 |

|

127 |

5” |

137 |

10 |

12 |

660 |

940 |

9.58 |

|

150 |

6” |

162 |

9 |

10 |

825 |

1075 |

14.00 |

|

175 |

7” |

187 |

5 |

9 |

1000 |

1200 |

16.00 |

|

200 |

8” |

215 |

4 |

8 |

1200 |

1400 |

20.00 |

High Pressure PTFE Hose

HIGH PRESSURE & ULTRA HIGH PRESSURE PTFE HOSE

Our ultra-high pressure hose series is constructed with a carbon black anti-static (conductive) PTFE post-sintered inner core and stainless steel wire braid reinforcement. The MHP and UHP series hose is the premiere product for rapid rate impulse applications.

This product is ideal for use in the gas industries and heavy duty applications.

We offer high pressure PTFE hose in both post-sintered (for gaseous and heavy duty applications) and nonpost-siintered (for most industrial applications) options.

Temperature rating: -65°F to 450°F

|

Nominal Size |

I.D |

O.D |

Min. Bend Radius |

Operating Pressure |

|

(in) |

(in) |

(in) |

(in) |

(psi) |

|

1/4 |

0.222 |

0.390 |

1.5 |

5,000 |

|

3/8 |

0.308 |

0.490 |

2.5 |

5,000 |

|

1/2 |

0.401 |

0.615 |

2.9 |

5,000 |

|

5/8 |

0.495 |

0.730 |

3.3 |

5,000 |

|

3/4 |

0.617 |

1.990 |

3.9 |

5,000 |

|

1 |

0.867 |

1.270 |

5.0 |

5,000 |

|

1 1/4 |

1.118 |

1.660 |

12.0 |

5,000 |

|

1 1/2 |

1.375 |

1.900 |

14.0 |

4,000 |

|

1/4 |

0.222 |

0.390 |

1.5 |

5,000 |

Convoluted PTFE Hose

CONVOLUTED PTFE HOSE

Self draining helical PTFE stainless steel wire reinforced hose ideal for demanding high purity and chemical applications.

Standard fitting material is stainless steel, steel and Halar encapsulated.

|

Nominal Size |

I.D |

O.D |

Min. Bend Radius |

Operating Pressure |

Min. Burst Pressure |

Max. Length |

|

(in) |

(in) |

(in) |

(in) |

(psi) |

(psi) |

(ft) |

|

1/2 |

0.512 |

0.785 |

1 |

1,000 |

4,000 |

75 |

|

3/4 |

0.750 |

1.090 |

2 |

1,000 |

4,000 |

50 |

|

1 |

0.998 |

1.300 |

3 |

1,000 |

4,000 |

50 |

|

1 1/4 |

0.239 |

1.560 |

6.25 |

1,500 |

4,000 |

50 |

|

1 1/2 |

0.500 |

1.792 |

7.5 |

750 |

3,000 |

50 |

|

2 |

0.982 |

2.333 |

10 |

500 |

2,500 |

50 |

Smooth Bore Teflon Hose

SMOOTHE BORE MED. PRESSURE PTFE HOSE

A smooth bore PTFE stainless steel wire reinforced hose designed for high purity applications and chemical extremes. An excellent choice for pharmaceutical, food and beverage applications.

Standard fitting material is stainless steel or brass.

|

Nominal Size |

I.D |

O.D |

Min. Bend Radius |

Operating Pressure |

Min. Burst Pressure |

|

(in) |

(in) |

(in) |

(in) |

(psi) |

(psi) |

|

3/16 |

0.125 |

0.234 |

2 |

3,000 |

15,000 |

|

1/4 |

0.187 |

0.312 |

2 |

3,000 |

14,000 |

|

5/16 |

0.0250 |

0.375 |

3 |

3,000 |

13,000 |

|

3/8 |

0.312 |

0.445 |

4 |

2,500 |

12,000 |

|

1/2 |

0.406 |

0.649 |

5.2 |

2,000 |

9,000 |

|

5/8 |

0.500 |

0.648 |

6.5 |

1,500 |

8,500 |

|

3/4 |

0.625 |

0.778 |

7.7 |

1,200 |

6,000 |

|

1 |

0.875 |

1.030 |

9 |

1,000 |

4,000 |

|

1 1/4 |

1.125 |

1.315 |

16 |

800 |

3,200 |

High Pressure Flexible Metal Hose

HPC High Pressure

Annular Corrugated Metal Hose

Principal Applications

HPC is ideal for the conveyance of all fluids at elevated pressures within a wide range of temperatures.

HPC being inherently leak proof is suitable for high pressure and heavy duty applications, in many instances replacing high pressure rubber hydraulic hose in high temperature environments.

Standards: Manufactured to the specifications where applicable of ISO 10380.

Supply Lengths: Random lengths of 10-30 metres depending upon diameter.

Product Cod: HPC_ _ _

Materials of Construction

Hose: AISI 304, AISI 316/L

Braid: AISI 304 (standard), AISI 316

|

Specifications Nominal bore |

Nominal bore |

Outside Dimensions |

Nominal Pressure |

Burst Pressure |

Static Bend Radius |

Dynamic Bend Raduis |

Weight |

|

(mm) |

(mm) |

(mm) |

(bars) |

(bars) |

(mm) |

(mm) |

(kg/M) |

|

6 |

1/4” |

13.0 |

255 |

1020 |

25 |

110 |

0.80 |

|

10 |

3/8” |

19.4 |

195 |

780 |

38 |

150 |

1.00 |

|

12 |

1/2” |

21.8 |

185 |

740 |

45 |

165 |

1.20 |

|

20 |

3/4” |

34.5 |

145 |

580 |

60 |

210 |

1.60 |

|

25 |

1” |

43.0 |

125 |

500 |

80 |

230 |

2.50 |

|

32 |

1 1/4” |

53.5 |

122 |

488 |

90 |

270 |

3.60 |

|

40 |

1 1/2” |

62.0 |

120 |

480 |

110 |

310 |

4.40 |

|

50 |

2” |

70.0 |

100 |

400 |

130 |

400 |

4.70 |

|

63 |

2 1/2” |

89.0 |

65 |

260 |

210 |

500 |

6.00 |

|

75 |

3” |

103.0 |

60 |

240 |

230 |

600 |

7.50 |

|

100 |

4” |

129.0 |

38 |

152 |

500 |

1000 |

9.00 |

|

125 |

5” |

157.0 |

32 |

128 |

560 |

1100 |

11.00 |

|

150 |

6” |

182.0 |

30 |

120 |

610 |

1200 |

16.00 |

Annular Corrugated Metal Hose

Annular Corrugated Metal Hose

Description

A corrugated flexible metallic hose with standard pitch annular corrugations, hydroformed from butt welded precision tube.

The depth and shape of the corrugations provides good flexibility and cycle life.

One or two layers of close weave metallic wire braid applied at the optimum angle is added to the outside of the hose to enhance the pressure capability of the hose. The hydroforming with water as the forming medium enables the corrugation to be formed from thicker material and and allows for the preferable deeper corrugations. This method of forming is also less stressful on the material assisting in a longer service life.

Principal Applications

Annular is ideal for the conveyance of liquids and gases in a wide range of temperatures from cyrogenic -200°C to over +500°C, however note as the temperature rises the pressure capability rating of the hose reduces.

The hose can be used for simple conveying of product, in-plant applications to correct pipework mis-alignment or with moving machinery and equipment. The hose being manufactured usually from stainless steel is suitable for a wide range of chemicals in corrosive situations.

In addition, the U-shape of the corrugations gives the hose a self draining feature, of particular interest in the food, plastics and bitumen industries requiring regular hose cleaning.

Materials of Construction

Hose: AISI 304, AISI 316/L

Braid: AISI 304 (standard), AISI 316

Other materials available on order.

Supply Lengths

Standard mill 5 metre lengths

Longer lengths available on order

Standards

Manufactured to the specifications where applicable of ISO 10380 Type 1-10 – Corrugated Metal Hose of High Flexibility with medium fatigue life.

|

Nominal bore

|

No. Braid Layers |

O.D |

W.P |

B.P |

Static Bend Raduis |

Dynamic Bend Radius |

Weight |

|

|

(mm) |

(inches) |

|

(mm) |

(bars) |

(bars) |

(mm) |

(mm) |

(kg/M) |

|

12 |

1/2 |

0 |

18.6 |

11 |

- |

24 |

165 |

0.12 |

|

1 |

20.2 |

80 |

320 |

45 |

0.32 |

|||

|

2 |

21.8 |

130 |

520 |

- |

0.53 |

|||

|

20 |

3/4 |

0 |

29.0 |

5 |

- |

35 |

225 |

0.27 |

|

1 |

30.6 |

65 |

260 |

70 |

0.57 |

|||

|

2 |

32.2 |

100 |

400 |

- |

0.88 |

|||

|

25 |

1 |

0 |

35.5 |

4 |

- |

42 |

260 |

0.36 |

|

1 |

37.3 |

50 |

200 |

85 |

0.75 |

|||

|

2 |

39.2 |

80 |

320 |

- |

1.15 |

|||

|

32 |

1 1/4 |

0 |

44.0 |

4 |

- |

51 |

300 |

0.46 |

|

1 |

46.5 |

40 |

160 |

105 |

1.07 |

|||

|

2 |

49.0 |

75 |

300 |

- |

1.70 |

|||

|

40 |

1 1/2 |

0 |

52.0 |

3 |

- |

61 |

340 |

0.65 |

|

1 |

54.5 |

38 |

152 |

130 |

1.47 |

|||

|

2 |

57.0 |

65 |

260 |

- |

2.30 |

|||

|

50 |

2 |

0 |

65.0 |

2 |

- |

73 |

390 |

0.80 |

|

1 |

67.5 |

32 |

128 |

160 |

2.00 |

|||

|

2 |

70.0 |

50 |

200 |

- |

3.30 |

|||

|

65 |

2 1/2 |

0 |

81.0 |

1.5 |

- |

90 |

450 |

1.20 |

|

1 |

83.5 |

23 |

90 |

180 |

2.70 |

|||

|

2 |

85.5 |

38 |

152 |

- |

4.20 |

|||

|

80 |

3 |

0 |

100.0 |

1.3 |

- |

108 |

520 |

1.85 |

|

1 |

103.0 |

20 |

80 |

240 |

3.60 |

|||

|

2 |

106.0 |

33 |

135 |

- |

5.40 |

|||

|

100 |

4 |

0 |

127.0 |

0.7 |

- |

126 |

660 |

2.50 |

|

1 |

130.0 |

15 |

60 |

290 |

5.10 |

|||

|

2 |

133.0 |

25 |

100 |

- |

7.80 |

|||

|

125 |

5 |

0 |

152.0 |

0.5 |

- |

150 |

850 |

3.60 |

|

1 |

155.0 |

14 |

56 |

340 |

6.80 |

|||

|

2 |

158.0 |

22 |

88 |

- |

10.00 |

|||

|

150 |

6 |

0 |

174.0 |

0.4 |

- |

- |

950 |

4.70 |

|

1 |

177.0 |

11 |

44 |

170 |

8.40 |

|||

|

2 |

180.0 |

17 |

68 |

400 |

12.10 |

|||

|

200 |

8 |

0 |

230.0 |

0.3 |

- |

500 |

1100 |

6.30 |

|

1 |

234.0 |

9 |

36 |

11.30 |

||||

|

2 |

238.0 |

13 |

52 |

16.50 |

||||

|

250 |

10 |

0 |

285.0 |

0.2 |

- |

700 |

1300 |

11.30 |

|

1 |

290.0 |

7 |

24 |

17.40 |

||||

|

2 |

295.0 |

9 |

36 |

23.80 |

||||

|

300 |

12 |

0 |

337.0 |

0.2 |

- |

900 |

1500 |

13.20 |

|

1 |

342.0 |

5 |

20 |

20.20 |

||||

|

2 |

347.0 |

7 |

20 |

28.00 |

||||

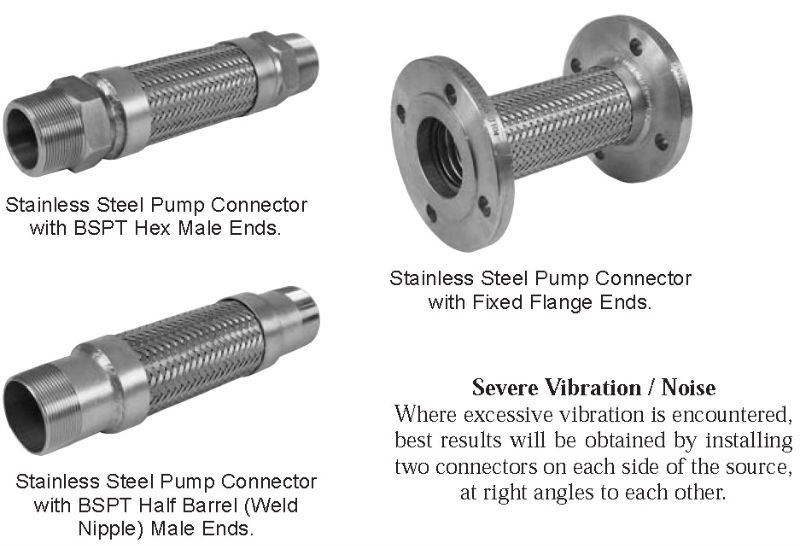

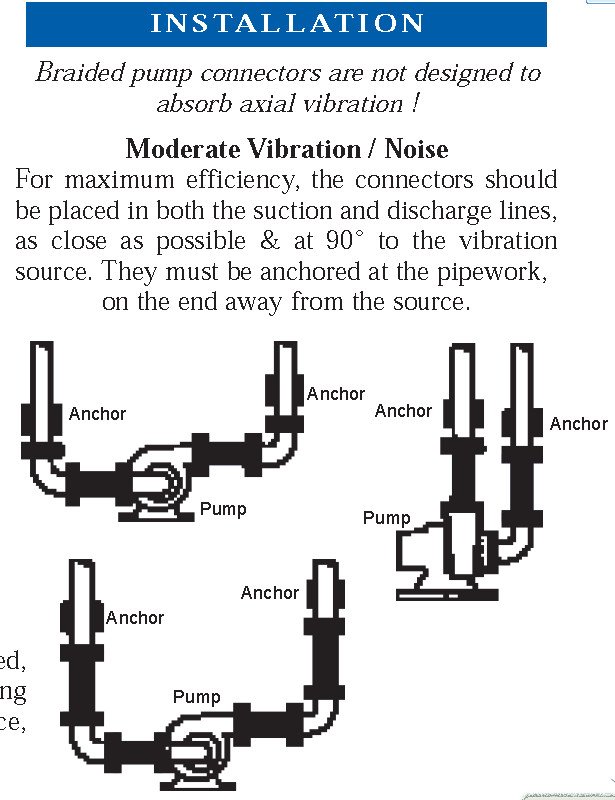

Flexible Pump Connector

Flexible Pump Connector

Specifications

Stainless Steel Hose

Single Stainless Braid

Male NPT Schedule 40 Carbon Steel Fittings

Options

Bronze Hose & Braid

Stainless Steel Fittings

Schedule 80 Fittings

Hex Nut Fittings

Double Braided For Higher Pressure

|

I.D (in.) |

Overall Length |

Max. W.P. At Room Temp. (psi) |

Approx. Wt. (lbs.) Per Unit |

|

1/2 |

6-1/2" |

950 |

1/2 |

|

3/4 |

7" |

700 |

1 |

|

1 |

8" |

550 |

1 |

|

1-1/4 |

8-1/2" |

420 |

1-1/2 |

|

1-1/2 |

9" |

380 |

2 |

|

2 |

10-1/2" |

300 |

2-1/2 |

|

2-1/2 |

12" |

300 |

2-1/2 |

|

3 |

14" |

250 |

4 |

|

4 |

16" |

200 |

4-1/2 |

Fuel and Oil Hose

Air and Water Hose

Smoothbore Water Hose 10bar

Smoothbore Water Hose 10bar

designed to convey water, non aggressive fluids and compressed air in various industrial and agricultural applications.

Tube: black, seamless synthetic rubber compound.

Reinforcement: high strength synthetic cord.

Cover: black, seamless synthetic rubber compound, ageing and weathering resistant

Temperature: from -30°C (-22°F) to +70°C (+158°F).

|

Inside Diameter |

Outside Diameter |

Working Pressure |

Burst Pressure |

Nominal Weight |

|||||

|

Mm inch |

Mm inch |

Bar psi |

Bar psi |

kg/m lbs/ft |

|||||

|

5 |

12/61 |

10,5 |

0,41 |

10 |

150 |

30 |

450 |

0,09 |

0,06 |

|

8 |

5/16 |

15 |

0,59 |

10 |

150 |

30 |

450 |

0,16 |

0,11 |

|

10 |

25/64 |

15 |

0,59 |

10 |

150 |

30 |

450 |

0,12 |

0,08 |

|

10 |

25/64 |

17 |

0,67 |

10 |

150 |

30 |

450 |

0,18 |

0,12 |

|

12 |

15/32 |

17 |

0,67 |

10 |

150 |

30 |

450 |

0,14 |

0,09 |

|

13 |

1/2 |

19 |

0,75 |

10 |

150 |

30 |

450 |

0,19 |

0,13 |

|

15 |

19/32 |

21 |

0,83 |

10 |

150 |

30 |

450 |

0,21 |

0,14 |

|

16 |

5/8 |

23 |

0,91 |

10 |

150 |

30 |

450 |

0,27 |

0,18 |

|

19 |

3/4 |

26 |

1,02 |

10 |

150 |

30 |

450 |

0,31 |

0,21 |

|

20 |

25/32 |

30 |

1,18 |

10 |

150 |

30 |

450 |

0,50 |

0,34 |

|

22 |

7/8 |

30 |

1,18 |

10 |

150 |

30 |

450 |

0,41 |

0,28 |

|

25 |

1 |

33 |

1,30 |

10 |

150 |

30 |

450 |

0,46 |

0,31 |

|

25 |

1 |

35 |

1,38 |

10 |

150 |

30 |

450 |

0,60 |

0,40 |

![]()

"Conduct our relationships with responsibility, honesty and loyalty. Cherish an excellent work environment with respect and cooperation at all levels. Offer products and services with quality, technology and competitiveness. "

Find us at

MAIN OFFICE:

Duqiao, Jingxian, Hengshui, Hebei Province, China

0086-188-3188-7776

sales@minghose.com

0086 -188 3188 7776

sales@mingflex.com

Monday - Saturday: 8:00 Am - 18:00 Pm

Sunday: Closed